Preventive maintenance is crucial for the longevity and efficiency of industrial electrical systems. Regular inspections and maintenance can identify potential issues before they become major problems, ensuring the continuous and safe operation of your facility. Here are some key benefits of preventive maintenance:

1. Enhanced Safety

Regular maintenance helps to identify and rectify electrical hazards, reducing the risk of accidents and ensuring a safer working environment.

2. Increased Equipment Lifespan

Proper maintenance extends the life of electrical equipment, saving costs on replacements and reducing downtime.

3. Improved Energy Efficiency

Well-maintained systems operate more efficiently, leading to lower energy consumption and reduced utility bills.

4. Minimized Downtime

Routine checks and timely repairs prevent unexpected breakdowns, ensuring smooth and uninterrupted operations.

Key Preventive Maintenance Practices

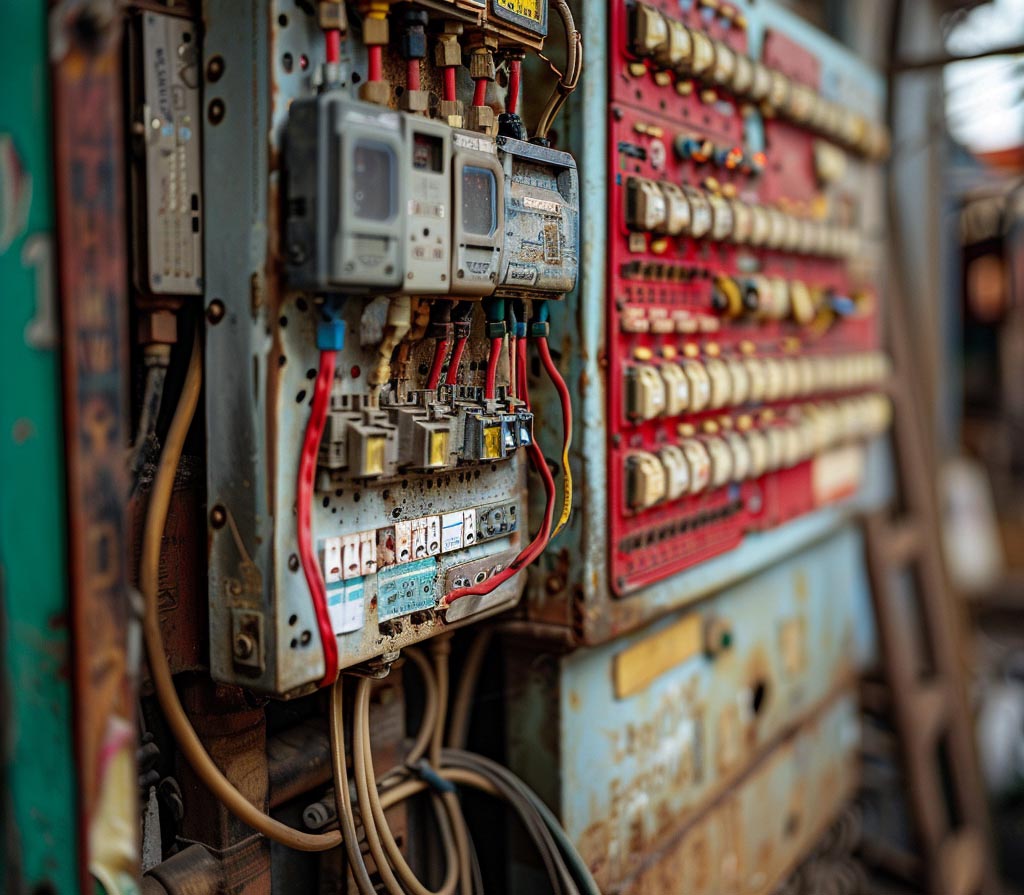

- Regular Inspections Schedule regular inspections of all electrical components to detect wear and tear or potential failures.

- Thermal Imaging Use thermal imaging to identify hot spots and overheating equipment that may indicate underlying issues.

- Cleaning and Tightening Connections Dirty or loose connections can lead to inefficiencies and failures. Regularly clean and tighten connections to ensure optimal performance.

- Testing and Calibration Periodically test and calibrate electrical systems to maintain accuracy and reliability.

Why Choose Eric Gandler Development Electric?

At Eric Gandler Development Electric, we offer comprehensive preventive maintenance services tailored to the unique needs of industrial facilities. Our experienced electricians use advanced tools and techniques to ensure your electrical systems are in top condition, providing peace of mind and operational efficiency.

Contact us today to schedule a preventive maintenance consultation and keep your industrial operations running smoothly.

For more insights and updates, visit our Facebook page.